helical end mills feeds and speeds

Basically what it boiled down to was stick with Helical. IPT IPM RPM X Number of Flutes MRR RDC X ADC X IPM aka.

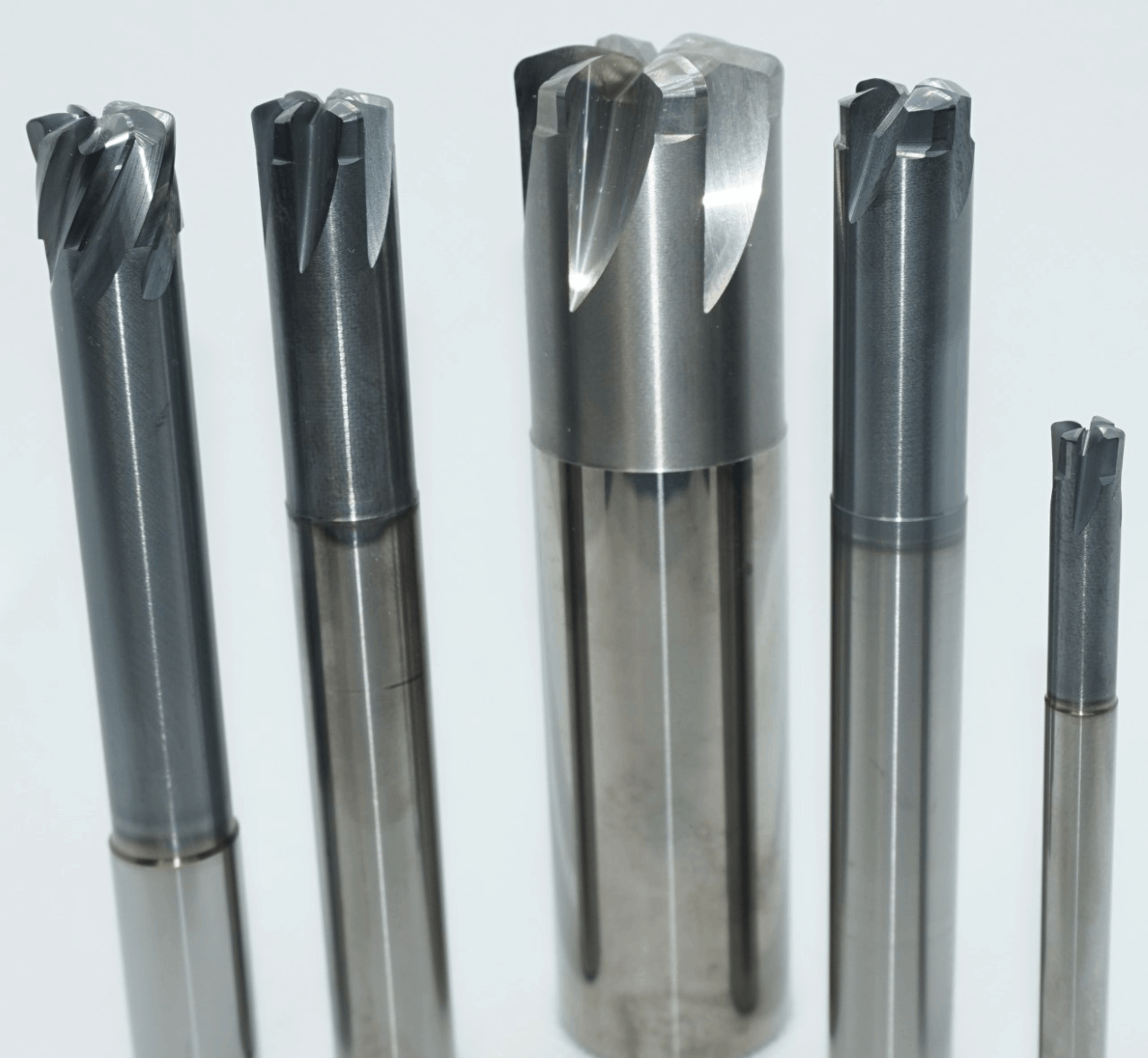

4 6 Flute High Feed End Mills Epic Tool

Helical speeds and feeds.

. Calculations use the desired tool diameter. 35 for light duty CNC Machines. They are predominantly used on CNC and manual milling machines but can also be used on router and.

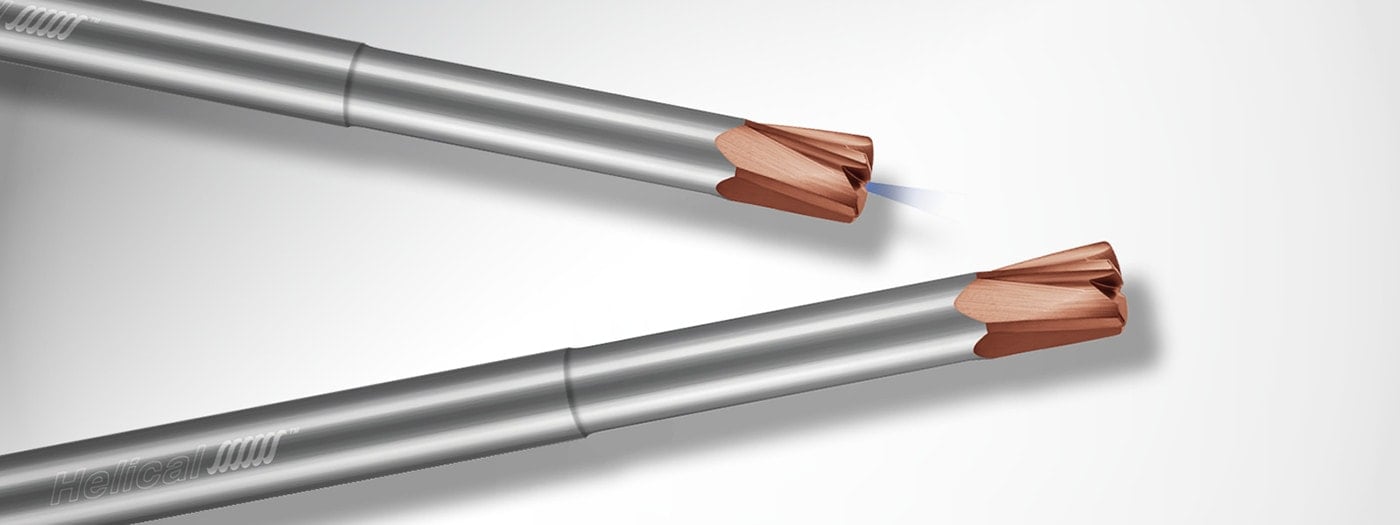

Helicals fully stocked offering of High Feed End Mills is designed for outstanding performance and maximum feed rates in aluminum and non-ferrous materials. I am creating a new calculator based on your feedback. They should also shorten your run time too.

We cut slots all day long in 4140. Helicals High Feed End Mills come coated with Tplus coating which offers high hardness and extended tool life in high temp alloys and ferrous materials up to 45Rc. End Mill Speed Feed Calculator.

A customer can find the SFM for the material on the left in this case 304 stainless steel. 38 Helix Cobalt End Mills. Simply search for your tool number and then click on Speeds Feeds in the resources section.

Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth such as an end mill or face mill. Its reduced neck geometry provides maximum strength in long reach and deep pocketing applications while its end profile provides optimal tool engagement and reduced cutting forces. Speeds and Feeds Master Library of Harvey Tools entire tool line up of Specialty End Mills Drills and Cutting Tools.

Ingersoll supplies almost all my carbide insert tooling and I asked him about the Ingersoll carbide end mills. RPM SFM X 382 Tool Diameter. Machining Advisor Pro quickly seamlessly and accurately calculates recommended speeds and feeds for running your Helical Solutions end mills.

Posted on January 31 2018 Leave a comment. Using MasterCam dynamic milling and whisperkuts end mills. Milling Speed and Feed Calculator.

View Speeds Feeds. MAP is our go-to solution for High Efficiency Milling and has exponentially decreased our run times as. For example the large partial radius of the Helical Solutions High Feed End Mill bottom cutting edge will leave a smaller scallop when compared to a ball end mill programmed with the same tool path.

Part of what makes Helical tools worthwhile is the. End Mill Speeds And Feeds - TiN Coated Carbide. New Helical Machining Advisor Pro.

Determining the right speeds and feeds for your tool and operation can be a complicated process but understanding the ideal speed RPM is necessary before you start running your machine to ensure proper tool life. TAPERED END MILLS HIGH SPEED STEEL FEED PER TOOTH ROUGHING AND FINISHING Material. Use the light roughing as described at the bottom of the chart.

Machining Advisor Pro paired with Helical End Mills is the Holy Grail of End Mill Performance. We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. 31 rows Geometry proven to achieve maximum feed rates in steels up to 45 Rc.

Figure 6 shows a side by side comparison. Dura-Mills WhisperKut Speed and Feed High Performance End. SMM RPM X 00314 X Tool Diameter.

Please fill out the form below with feeds and speeds that work for you and I will place them into a new database for all to use. Speeds and Feeds 101 October 2. A feature on a variety of high.

Combination Feed HEM - 5 Flute - Chipbreaker Rougher - Variable Pitch This offering of High Feed End Mills used for both high feed and High Efficiency Milling HEM applications features tooling with offset chipbreaker geometry for optimal chip evacuation minimized harmonics and reduced tool pressure. Check out the speeds and feeds chart. Feeds - IPT inchestooth and MMPT mmtooth Material.

SMM SFM X 3048. In Roughing Applications on a CNC Mill we have found the Fastest and Most Cost Effective way to machine is to use an Optimized Tool Path Software like Volumill DynamicMill or iMachining along with a High Performance Variable Pitch End Mill. Machining Advisor Pro MAP is a cutting-edge resource that generates custom running parameters for optimized machining with Helical Solutions end mills by pairing your end mill with your exact tool path material and machine setup.

This blog covers speeds and feeds for milling. 78 to 1 Aluminum 6061. Running a tool too fast can cause suboptimal chip size or even catastrophic tool failure.

Determine the spindle speed RPM and feed rate IPM for a milling operation as well as the cut time for a given cut length. I would use a 58 WhisperKut from Dura-Mill. There are many types of end mill cutters which are defined by their design geometries.

You can read more about common machine problems on our End Mill Troubleshooting page. Cobalt Aerocut Roughing End Mill. IPM RPM X IPT CLPT X Number of Flutes.

Curvature of the Bottom Edge of High Feed End Mills. In addition to our Speeds Feeds Library you can also find specific running parameters directly on our product page and tool details page for every tool. They are often referred to as milling bits or router bits.

An Optimized Tool Path will lay out a tool path that will always keep a con. SFM RPM X 262 X Tool Diameter. Helical end mills are meticulously designed for maximum rigidity to support aggressive speeds and feeds.

Harvey Tool provides the following chart for a 18 diameter end mill tool 50308. The smaller the radius of curvature the larger the height of the scallop. Dr Rough diameter of work piece.

Aph Z-axis depth for one helical revolution circular 0. A flat-ended chamfer cutter with helical flutes has a tip diameter of 060. If playback doesnt begin shortly try restarting your device.

Stainless Steel 304 302. In summary these tools with specialized end geometry that utilizes chip thinning and light axial depths of cut to allow for significantly increased feed rates in face milling slotting roughing deep pocket. An endmill bit is a helical rotating cutting tool that can be used for milling operations.

Mild - 1018 2-3 Carbon 420 0006016mm 0011028mm 0017043mm 002051mm. Aps Starting axial depth of cut. This offering of High Feed End Mills used for both high feed and High Efficiency Milling HEM applications features tooling with offset chipbreaker geometry for optimal chip evacuation minimized harmonics and reduced tool pressure.

Accusize Industrial Tools 3 4 Inch M42 8 Cobalt Tialn Roughing End Mill 3 4 In Shk Dia 1 5 8 In Flute Length Fine Tooth 1104 0034 Amazon Ca Industrial Scientific

Speeds Feeds 101 Feeding Speed Food

5 Things To Know About Helical S High Feed End Mills In The Loupe

Fazd Trade Co Limited Machine Shop Power Tool Accessories End Mill

High Performance End Mills Mastercut Tool Corp Endmills

Titanium Machining Guide Titanium Make It Simple Milling

5 Things To Know About Helical S High Feed End Mills In The Loupe

5 0 X 5 0 X 0 500 Dp Square Pocket With Square Island Main Program O02010 T1 M06 Tool Is A 0 500 Diameter Endmi Cnc Programming Programming Tutorial Cnc

Series 6773 Inch Rf100 Speed 4 Fl Std Length End Mill Guhring

Technology Spotlight High Speed Trochoidal Tools

Mill 1 10 Helical Indexable Helical End Mills